Solvent-free materials, odorless, environmentally friendly and healthy products, fully in line with the national standard GB 36246-2018.

Spray Coating PU Running Track is engineered as a high‑performance athletics surface optimized for stadiums, schools, community sports fields and renovation projects. Its multi‑layer spray coating system combines durability, weather‑resistance and athlete safety in one cost‑efficient solution.

Solvent-free materials, odorless, environmentally friendly and healthy products, fully in line with the national standard GB 36246-2018.

The base glue can be formed in one step, has good leveling properties, and is easy to construct.

Strong elasticity, strong weather adaptability, and no bubbling and hollowing.

The spray glue has a 1:1 formula, strong encapsulation of granules, and is not easy to fall off.

The surface spray glue uses imported pigments, with long-lasting color and excellent wear resistance.

Spray coating surface is 100 % waterproof and can stretch up to 400 %, delivering remarkable flexibility and resilience even under extreme weather conditions.

Solvent‑free and odorless construction ensures safer installation and use in sensitive environments such as schools and public parks.

Exceptional resistance to UV, frost, heavy rain and chemical corrosion ensures long‑term performance with minimal cracking or deterioration.

Adhesion is excellent across a variety of base surfaces and the system supports fast installation, reducing downtime in facility upgrades.

| Physical properties | ||||||

| Inspection items | Tensile strength | Elongation at break ( % ) | Shock absorption | Vertical deformation ( mm ) | Sliding-resistance value | Flame retardant properties |

| Detecting data | 1.26MPA | 171% | 35%-50% | 2.4mm | 78BPN, 20℃ | Level I |

| Chemical properties | ||

| Project | Standard | Detecting data |

| Total Volatile Organic Compounds (TVOC): 2.2 | The sum of three phthalates (DBP, BBP, DEHP): Not detected | Benzene: Not detected |

| Formaldehyde:0.06 | The sum of three phthalates (DNOP, DINP, DIDP): Not detected | Soluble lead: Not detected |

| Toluene, xylene, and ethylbenzene total: 0.01 | 4,4'-Diamino-3,3'-dichlorodiphenylmethane (MOCA): Not detected | Soluble cadmium: not detected |

| Odor level ≤ 3 grades | Free diphenylmethane diisocyanate (MDI): Not detected | Soluble chromium: Not detected |

| Carbon disulfide: Not detected | Sum of 18 polycyclic aromatic hydrocarbons: Not detected | Soluble mercury: Not detected |

| Short-chain chlorinated paraffins (C10-C13): Not detected | Free toluene diisocyanate (TDI) and free hexamethylene diisocyanate (HDI) total: not detected | Benz[a]pyrene: Not detected |

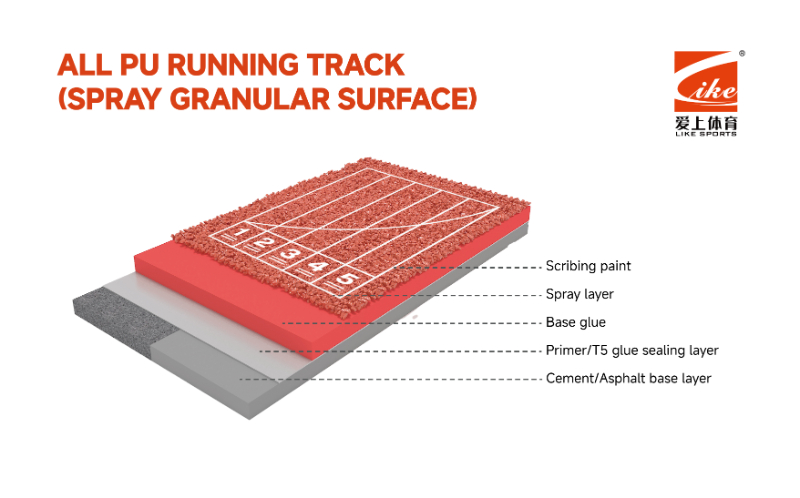

The base layer inspection - The base layer treatment - The base layer sealing- Base glue layer construction - Grinding and repairing - Strengthen layer construction - Grinding and repairing - granular spraying layer- Scribing line- Site acceptance

New athletic stadiums: The system meets international athletics standards, offering textured spray granular top‑layer finish with consistent traction for competitive events.

School and university sports fields: The eco‑conscious design and rapid install allow safe, reliable surfaces for daily physical education and training.

Community fitness parks & jogging paths: Thanks to its strong weather and wear resistance, the Spray Coating PU system is ideal for high‑traffic public spaces and outdoor pathways.

Renovation of old tracks: The system can be applied over existing concrete or asphalt substrates, enabling fast renewal of aging tracks with minimal disruption.

Choosing the Spray Coating PU Running Track means investing in a surface that blends spray coating technology, polyurethane durability, and low‑maintenance design. The textured granular spray coat enhances grip, the full poly material base improves longevity, and the system’s versatility ensures it can be adapted to many installation scenarios. With an expected service life that outperforms traditional systems, it’s a smart solution for both new builds and refurbishment.

Please leave message

Please leave message

+86 181 2230 3341