Mold foaming, rotary cutting, uniform thickness. Rotary cutting seamless technology standardized fully automatic process production, precise control of product thickness (thickness error is only ±0.1mm).

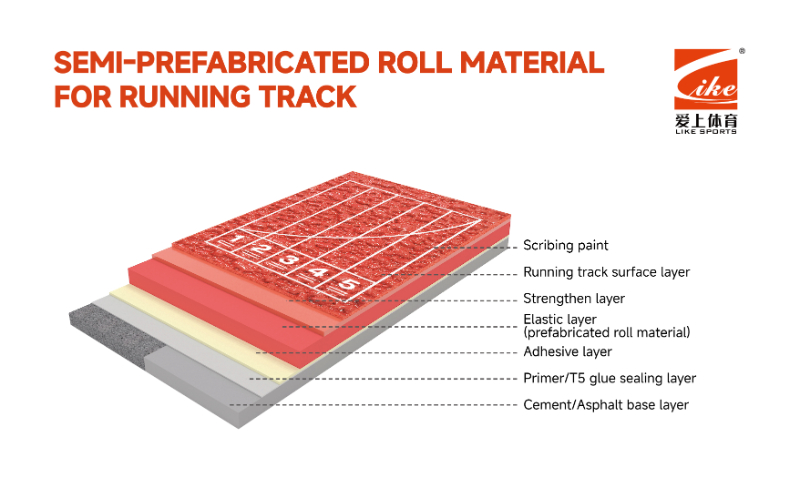

Semi Prefabricated Running Track developed by LIKE SPORTS represents the next generation of athletic surface technology — a hybrid system that perfectly balances the precision of prefabrication with the flexibility of on-site installation. This semi-prefabricated roll material for running track is produced in controlled factory conditions, ensuring consistent density and elasticity, then seamlessly bonded and finished on site to create a continuous, joint-free surface.

◎Mold foaming, rotary cutting, uniform thickness. Rotary cutting seamless technology standardized fully automatic process production, precise control of product thickness (thickness error is only ±0.1mm).

◎Factory prefabrication ensures flatness and seamless integration! The material does not deform, warp, arch, or crack.

◎High-density polymer products have excellent elasticity and shock-absorbing functions. It is resistant to compression deformation, bending and friction.

◎Good durability, no displacement cracking due to thermal expansion and contraction; high and low temperature resistance, the material can adapt to ambient temperatures of -40℃ to 80℃ after curing.

◎Excellent mechanical properties, elongation at break reaches 2 times the standard of GB36246-2018, and tensile strength reaches 1.5 times the standard of the new national standard.

◎100% of on-site sampling passes the new national standard.

◎Factory prefabricated products do not require any auxiliary materials to be added during construction, greatly shortening the construction period. Reducing construction periods by up to 40%.

◎The semi-prefabricated running track features an independent surface layer that can be re-sprayed or refinished without replacing the entire system, extending the track’s lifespan and reducing maintenance costs.

◎The semi-prefabricated roll material installs easily on multiple base types, including asphalt, concrete, and refurbished existing tracks, ensuring wide adaptability for both new construction and renovation projects.

◎Manufactured using advanced polyurethane technology, the running track is free from plasticizers, heavy metals, and toxic additives. Its low VOC formulation ensures safety for athletes and environmental compliance with modern green building standards.

Physical properties | ||

| Inspection items | Technical requirements | test data |

| Impact Absorption (%) | 35~50 | 0℃: 38 10℃: 41 |

| (10℃, 20℃, 23℃, 30℃, 40℃) | 20℃: 42 23℃: 43 | |

| 30℃: 44 40℃: 46 | ||

| 50℃: 47 | ||

| Vertical deformation ( mm ) | 0.6~2.5(10℃, 20℃, 23℃, 30℃, 40℃) | 0℃: 1.2 |

| 20℃: 1.423℃: 1.4 | ||

| 30℃: 1.540℃: 1.6 | ||

| 50℃: 1.7 | ||

| ( B P N , 2 0 ℃ )sliding-resistance value/( B P N , 20 ℃ ) | ≥47 | 60 |

| Tensile strength / ( M P a ) | ≥0.5 | 0.99 |

| Elongation at break / ( % ) | ≥40 | 91 |

| Flame retardant properties / (level) | Level I | Level I |

Chemical properties | ||

| Project | Standard | Detecting data |

| 3 types of phthalate compounds (DBP, BBP, DEHP) total a/ (g/kg) | ≤1.0 | Not detected |

| 3 types of phthalate compounds (DNOP, DINP, DIDP) total a/ (g/kg) | ≤1.0 | Not detected |

| Sum of 18 polycyclic aromatic hydrocarbons b/(mg/kg) | ≤50 | Not detected |

| ≤20c | Not detected | |

| Benz[a]pyrene / (mg/kg) | ≤1.0 | Not detected |

| Short-chain chlorinated paraffins (C10-C13) / (g/kg) | ≤1.5 | Not detected |

| 4,4'-Diamino-3,3'-dichlorodiphenylmethane (MOCA) / (g/kg) | ≤1.0 | 0.5 |

| Free Toluene Diisocyanate (TDI) and Free Hexamethylene Diisocyanate (HDI) Sum / (g/kg) | ≤0.2 | Not detected |

| Free diphenylmethane diisocyanate (MDI) / (g/kg) | ≤1.0 | Not detected |

| Soluble lead / (mg/kg) | ≤50 | 4 |

| Soluble cadmium / (mg/kg) | ≤10 | Not detected |

| Soluble chromium / (mg/kg) | ≤10 | Not detected |

| Soluble mercury / (mg/kg) | ≤2 | Not detected |

| Total Volatile Organic Compounds (TVOC) / (mg/(m²•h)) | ≤5.0 | 2.4 |

| Formaldehyde / (mg / (m²•h)) | ≤0.4 | 0.05 |

| Benzene/(mg/(㎡•h)) | ≤0.1 | Not detected |

| Toluene, xylene, and ethylbenzene total / (mg/(m²•h)) | ≤1.0 | 0.05 |

| Carbon disulfide / (mg/(m²•h)) | ≤7.0 | Not detected |

| Odor level/level | ≤3 | 3 |

The base layer treatment - The base layer sealing- Adhesive layer construction - Semi-prefabricated material laying - strengthen layer application- Spraying surface layer - Scribing line- Site acceptance

University and school sports grounds seeking fast installation and safe, comfortable running surfaces.

Municipal fitness parks that require cost-effective, durable athletic flooring with minimal maintenance.

Professional athletics stadiums that demand IAAF-compliant performance with flexible design options.

Sports complex renovations, where the semi-prefabricated structure minimizes demolition work and waste.

At LIKE SPORTS, our semi‑prefabricated roll‑material system offers a high‑quality running track surface combining durability, comfort, and professional‑level performance.

Elastic PU Binder Topcoat System Running Track Surface: provides excellent elasticity and a smooth finish. This system ensures a comfortable running surface that absorbs impact, delivering long-term performance and consistency under frequent use.

Sandwich System Running Track: engineered with a multi-layer structure — rubber cushion layer bonded with PU binder, sealed and topped with a durable PU wear coat, often finished with EPDM granules for added grip. This layered construction offers good shock absorption, strong adhesion, and excellent weather resistance, making it suitable for schools, community sports grounds, or professional athletic facilities.

PU Synthetic Running Track With WA Certificate: We offer a PU Synthetic Running Track With WA Certificate, built to meet rigorous quality standards. This ensures the surface is resistant to UV, abrasion, and weather conditions — ideal for outdoor tracks that need longevity and stable performance.

Athletic Sandwich Running Track: Athletic Sandwich Running Track from LIKE SPORTS is designed for athletic and training use. Its resilient base layer plus PU topcoat delivers reliable shock absorption and excellent durability, giving athletes a safe, consistent surface for running, training, and competition — even under heavy use over time.

Please leave message

Please leave message

+86 181 2230 3341