Both the bottom and the top are made of polyurethane, with a polymer content of >90%, and have good resistance to compression deformation, bending and abrasion.

Semi‑Prefabricated Sports Court Roll Material is a high‑performance surface solution designed specifically for sports courts in schools, universities, community recreation centers and commercial sports facilities. This roll format, semi‑prefabricated in nature, offers a unique combination of factory‑controlled precision and onsite adaptability. With consistent thickness and material density achieved in production, the Semi‑Prefabricated Sports Court Roll Material delivers reliable shock absorption, uniform rebound and long‑term durability in heavy use areas.

◎ Both the bottom and the top are made of polyurethane, with a polymer content of >90%, and have good resistance to compression deformation, bending and abrasion.

◎ Mold foaming, rotary cutting, uniform thickness. The rotary cutting seamless technology is used to standardize the automatic production process, accurately control the thickness, and the error is only ±0.1mm.

◎ The product absorbs 35%-38% of the impact, 1.2-1.5mm of vertical deformation, and the elongation at break is 2 times the GB 36246-2018 standard, and the tensile strength is 1.5 times.

◎ The TVOC index is far lower than the national standard. It does not contain plasticizers and heavy metals during the production and installation of the product, and no auxiliary materials are added during the construction process. It is less affected by the weather and has a short construction period.

Physical properties | ||

| Inspection items | Technical requirements | test data |

| Impact Absorption / (%) | 20~50 | 0℃±2℃:3826℃±2℃:3950℃±2℃:38 |

| Vertical deformation/ ( m m ) | 0.6~3.0 | 1.1 |

| ( B P N , 2 0 ℃ )sliding-resistance value/( B P N , 20 ℃ ) | 80~110(Dry measurement) | 105 |

| Tensile strength / ( M P a ) | ≥0.5 | 1.44 |

| Elongation at break / ( % ) | ≥40 | 101 |

| Flame retardant properties / (level) | Level I | Level I |

Chemical properties | ||

| Project | Standard | Detecting data |

| 3 types of phthalate compounds (DBP, BBP, DEHP) total a/ (g/kg) | ≤1.0 | Not detected |

| 3 types of phthalate compounds (DNOP, DINP, DIDP) total a/ (g/kg) | ≤1.0 | Not detected |

| Sum of 18 polycyclic aromatic hydrocarbons b/(mg/kg) | ≤50 | Not detected |

| ≤20c | Not detected | |

| Benz[a]pyrene / (mg/kg) | ≤1.0 | Not detected |

| Short-chain chlorinated paraffins (C10-C13) / (g/kg) | ≤1.5 | Not detected |

| 4,4'-Diamino-3,3'-dichlorodiphenylmethane (MOCA) / (g/kg) | ≤1.0 | 0.9 |

| Free Toluene Diisocyanate (TDI) and Free Hexamethylene Diisocyanate (HDI) Sum / (g/kg) | ≤0.2 | Not detected |

| Free diphenylmethane diisocyanate (MDI) / (g/kg) | ≤1.0 | Not detected |

| Soluble lead / (mg/kg) | ≤50 | Not detected |

| Soluble cadmium / (mg/kg) | ≤10 | Not detected |

| Soluble chromium / (mg/kg) | ≤10 | Not detected |

| Soluble mercury / (mg/kg) | ≤2 | Not detected |

| Total Volatile Organic Compounds (TVOC) / (mg/(m²•h)) | ≤5.0 | 1.5 |

| Formaldehyde / (mg / (m²•h)) | ≤0.4 | 0.02 |

| Benzene/(mg/(㎡•h)) | ≤0.1 | Not detected |

| Toluene, xylene, and ethylbenzene total / (mg/(m²•h)) | ≤1.0 | 0.02 |

| Carbon disulfide / (mg/(m²•h)) | ≤7.0 | Not detected |

| Odor level/level | ≤3 | 3 |

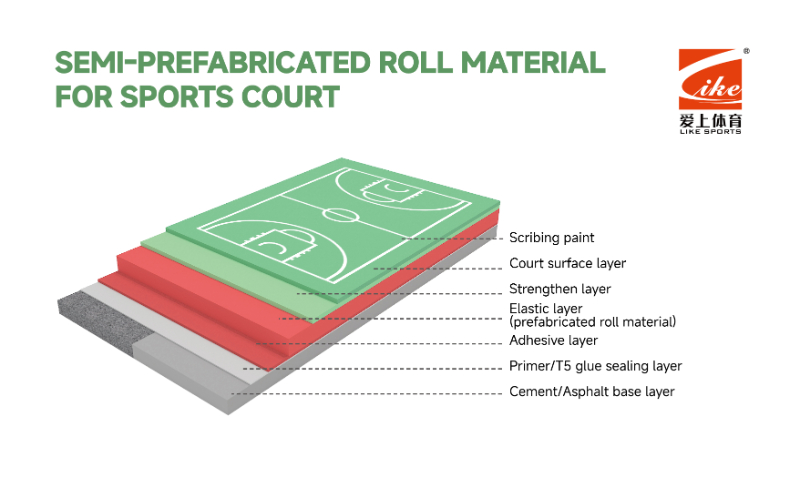

The base layer treatment - The base layer sealing- Adhesive layer construction - Semi-prefabricated material laying - strengthen layer application- Court surface layer construction - Scribing line- Site acceptance

Educational Facilities: The Semi‑Prefabricated Sports Court Roll Material is perfect for gymnasiums, indoor multi‑purpose courts and outdoor school courts that require a safe, low‑maintenance surface. Its resilient structure supports daily activities, PE classes and sports training, offering the dependable surface behavior expected from premium sports flooring.

Community and Public Sports Courts: For public sports venues, the Semi‑Prefabricated Sports Court Roll Material provides excellent durability under frequent foot traffic and environmental exposure. Its roll form simplifies maintenance and repair, and the semi‑prefabricated nature ensures minimal disruption during installation or refurbishment.

Commercial & Multi‑Use Sports Facilities: In commercial fitness centers, multi‑sport courts and training venues, the Semi‑Prefabricated Sports Court Roll Material demonstrates robust performance in terms of wear resistance, consistent playing feel and adaptability over various sub‑bases.

Renovation and Upgrades: When upgrading older courts or converting existing surfaces (such as asphalt or concrete slabs) into high‑quality sports courts, the Semi‑Prefabricated Sports Court Roll Material shines through. Its roll installation enables faster project schedules, reduced downtime and improved cost‑efficiency while retaining long‑term structural integrity.

Please leave message

Please leave message

+86 181 2230 3341